What is a Webster Hardness Tester?

The Webster Hardness Tester is a high-tech product integrating optical, mechanical, and electrical technologies. This machine features a novel design and offers excellent reliability, operability, and intuitiveness. It is a new type of Webster and Knoop hardness testing instrument that employs mechanical and photoelectric technologies. It has a variety of test forces, and as long as the surface roughness of the workpiece meets the standards, it can be tested.

Its working principle is similar to that of the portable brinell hardness tester. It uses a load of 49.03-980.7N to press a square pyramid diamond indenter with an included angle of 136° onto the material surface. After maintaining the load for a specified period, the hardness is calculated by measuring the length of the indentation diagonals and applying a formula. It is suitable for measuring the hardness of larger workpieces and deeper surface layers.

The webster hardness tester also includes small load Webster hardness and micro Webster hardness testing. The small load Webster hardness test uses a load of less than 49.03N and is suitable for measuring the hardness of thinner workpieces, tool surfaces, or coatings. The micro Webster hardness test uses a load of less than 1.961N and is suitable for measuring the hardness of metal foils and thin surface layers.

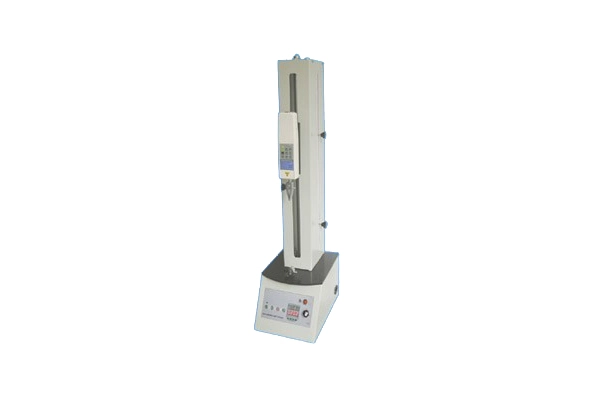

Introduction to the Webster Hardness Tester (W20)

The Webster Hardness Tester (W20) is suitable for measuring the hardness of aluminum alloys (including tubes, plates, and various aluminum components) and other soft metals. It helps determine whether aluminum products have been properly aged and meet the required standards. Additionally, it can distinguish between various types of aluminum and their aging states. The Webster Hardness Tester is ideal for on-site testing in large-scale production environments and sales areas, including quick, non-destructive evaluations of aluminum profiles, doors, windows, curtains, and walls.

The Webster Hardness Tester is easy to operate: simply clamp the workpiece and directly read the hardness value. It is designed for efficiency and reliability, conforming to the Chinese nonferrous metals standard YS/T420-2000 and the American standard ASTM B647-84 (2000).

Applications of the Webster Hardness Tester

The Webster Hardness Tester, a type of non destructive testing instruments, is widely used for hardness measurement of fine and small components. It is suitable for the hardness assessment of various materials and micro-sized products. Specifically, it is commonly used to measure the following types of materials and components:

Micro parts

Suitable for high-precision hardness testing of small mechanical parts such as watch parts, micro bearings, and medical instruments. These parts are small in size and have fine surfaces that require uniform hardness, and the Webster Hardness Tester provides stable and reliable test results.

Thin steel sheets and metal foils

The Webster Hardness Tester can measure metal materials with thinner thicknesses, such as thin steel sheets and metal foils. For materials with uneven thickness, the Webster Hardness Tester offers a high sensitivity and adaptability in hardness measurement, ensuring test accuracy.

IC wafers and wires

Materials in the electronics industry, such as IC wafers and wires, are typically very fine and fragile. The Webster Hardness Tester is suitable for hardness testing of these materials, helping to ensure the durability and stability of these microelectronic components in use.

Thin hardened layers and electroplated layers

As one of leading and professional portable hardness tester suppliers, our Webster Hardness Tester can accurately measure thin layers of materials with high surface hardness, such as hardened metal layers or electroplated layers. This is crucial for evaluating the wear resistance and corrosion resistance of materials, especially in manufacturing and aerospace fields.

Glass, jewelry, and ceramics

These materials are often brittle and have high hardness, making them difficult to measure with traditional hardness testers. The Webster Hardness Tester achieves precise testing through small indentations, making it particularly suitable for detecting high-hardness materials like glass, gemstones, and ceramics, meeting the high requirements for hardness measurement in jewelry, art, and specialty materials industries.

In summary, the Webster Hardness Tester, with its high precision and flexibility, becomes an ideal tool for hardness testing of various fine materials, micro parts, and special materials, widely serving the manufacturing, electronics, aerospace, jewelry, and new materials research fields.

français

français Español

Español русский

русский العربية

العربية português

português