Technical Parameters of W-20 Webster Hardness Tester

Range | 0-20 HW (the equivalent of 20-110 HRE) |

Indicator Error | 0.5 HW (5 -17 HW) |

Repeatability Error | 0.5 HW (5 -17 HW) |

Weight | 0.5 kg |

Maximum specimen thickness | compare according to opening size and model |

Minimum sample inner diameter | compare according to the anvil size and model |

Accesorries of W-20 Webster Hardness Tester

1. Indenter

With imported special steel material, new manufacturing technology , Higher hardness, excellent toughness, Long life, good interchangeability. imported packaging from Germany, Have comprehensive protection for the indenter.

2. Indicator Hand

High strength’s pointer: no easy bending deformation after long time using or wrong operation.

3. Dial Glass

High strength and high toughness’ dial glass, No easy to break after shocking.

4. Handle

Forged aluminum alloy material, Anodic oxidation handle. Handle friendly, wear-resistant, pollution- resistant.

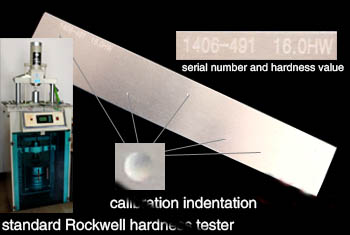

5. Hardness Blocks

Use standard Rockwell hardness blocks, with strict accordance to the metrological verification regulations. The number and hardness values with laser etching. Data in the validity can be traced to check. The surface roughness and flatness conform to the requirements of regulations.

6. High-quality

Well parts processed, Precision of machine assembly, High quality inspection, Ensure the equipment of high standard.

7. Stability

Stability with full scale values, Calibration points stability, Pointer no "crawl".

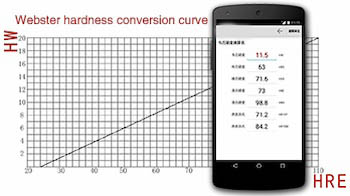

8. Conversion

Attached conversion list through product manual or "hardness conversion" applications, Webster hardness values can be converted to Vickers, Rockwell and Brinell hardness value.

9. Portability

The high quality portable instrument box fits for sponge buffer very well. No only provide portability for instruments but also offer the maximum protection at same time.

Comparison of W-20 Webster Hardness Tester

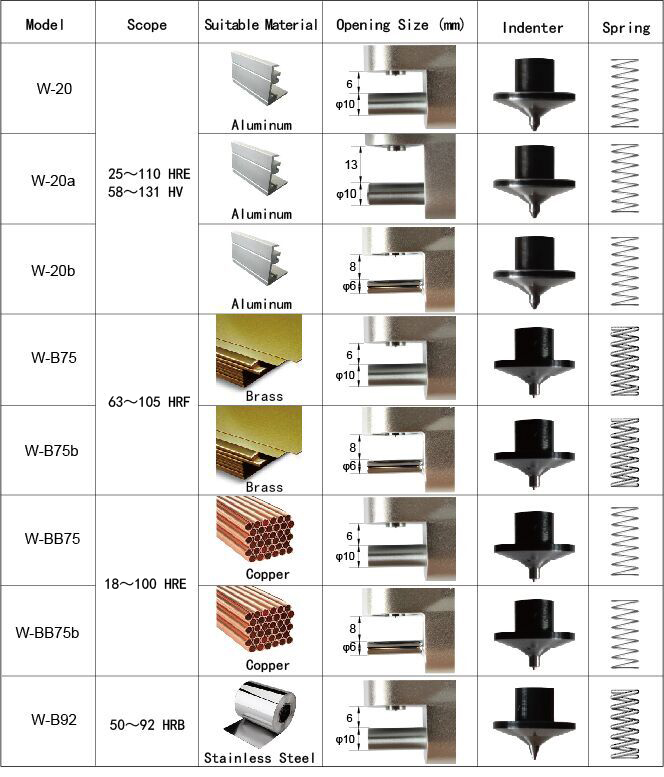

W-20 series include three models:

W-20 Webster hardness tester mainly use for inspect aluminum alloy, tube and plate.

W-20a can inspect industrial aluminum extrusions, plates or parts which have the thickness upper limit to 13 mm.

W-20b test small aluminum profiles or aluminum profiles pipes which have the inner diameter over 6 mm.

W-B75, W-BB75 Webster hardness tester inspects copper alloy, and W-B92 Webster hardness tester inspect stainless steel, especially suit for testing the hardness of materials such as mild steel, copper, brass.

MODELS

W-20 | Very popular model, used to inspect normal aluminum profiles. Working pieces requirements: Thickness 0.4-6mm,inner diameter>10mm. |

W-20a | inspect aluminum profiles with working pieces' thickness within 13 mm. |

W-20b | inspect aluminum tubing with working piece inner diameter over 6mm. |

WB75 | Inspect brass tubing and brass sheets. Woking piece thickness 0.4-6mm, inner diameter>10mm. |

W-B75b | Inspect brass tubing and brass sheets. Woking piece thickness 0.4-8mm, inner diameter>6mm. |

WBB75 | Inspect copper tubing and copper sheets. Woking piece thickness 0.4-6mm, inner diameter>10mm. |

W-BB75b | Inspect copper tubing and copper sheets. Working piece thickness 0.4-8mm,inner diameter>6mm. |

W-B92 | Inspect soft stainless steel sheets, cold-rolled steel, etc. Working piece thickness 0.4-6mm,inner diameter>10mm. |

Standard Delivery of W-20 Webster Hardness Tester

| STANDARD ASSEMBLY: |

| Tester |

| Standard hardness block |

| Spare indenter |

| Calibration wrench |

| Small screwdriver |

| Carrying case |

| Dial assembly |

Optional Delivery of W-20 Webster Hardness Tester

| OPTIONAL ACCESSORIES: |

| Indenter |

| Standard hardness block |

| Dial glass |

français

français Español

Español русский

русский العربية

العربية português

português