Hardness is a characteristic of a material, is important physical property. It is regarded as the resistance to indentation, and it is decided by measuring the depth of the indentation. Just simply put, when using a fixed loading force and a given indenter, the shallow indentation, the harder the material.

Indentation hardness value is had by measuring the depth or the area of the indentation using one of about 12 different test methods.

The Rockwell hardness testing method, is in ASTM E-18 and is the most commonly used hardness testing method. You need know this standard and understand the standard completely before using a Rockwell test.

The Rockwell test is easier to perform, and very accurate than other types of hardness testing methods. The Rockwell test method could be used for all metals, except in condition of metal structure or surface conditions would cause much variations; or the indentations is too large force for the application; or where the sample size or sample shape can not be its use.

The Rockwell hardness method make the permanent depth of indentation by a force/load on an indenter. First, preload or minor load then major load, it is added to reach the total required test load. Then returning to the preliminary load. After holding the preliminary test force for a specified dwell time, the final depth is measured. The Rockwell hardness value is from the difference in the baseline and final depth values. This distance is converted to a hardness number. The preliminary test force is over and the indenter is removed from the test piece.

Preloads test loads range from 3 kgf (used “Superficial” Rockwell scale) to 10 kgf (used in the “Regular” Rockwell scale). Total test forces range from 15kgf to 150 kgf (superficial and regular) to 500 to 3000 kgf (macrohardness).

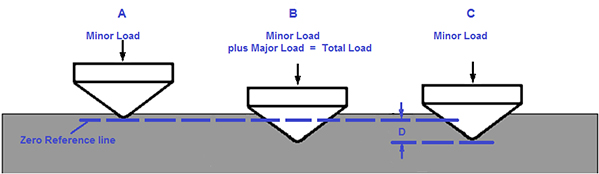

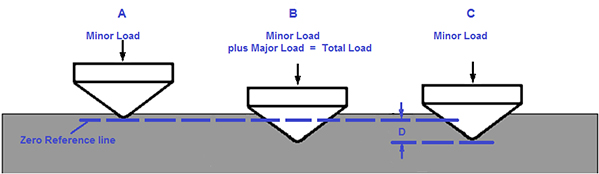

Test Method showing

A = Depth reached by indenter by preload (minor load)

B = Position of indenter at Total load, Minor plus Major loads

C = Final position reached of indenter after elastic recovery of material

D = Distance measurement taken representing difference between preload and major load position. This distance is used to calculate the Rockwell Hardness Number.

Rockwell Hardness tester recommended models: KHT800-A; KHT800-M

Superficial Rockwell & Rockwell hardness tester : KHT900-A; KHT900-M

français

français Español

Español русский

русский العربية

العربية português

português