Image | Description |

| KS55 - Extending Rod/bar, extending rod increases the depth and length for pickup to enter the part. extending 50mm long. |

| KS90 - Right Angle Rod/bar, changes the position of the sensor, mostly use for measure surface of especial groove. |

| KS100 - Small Hole Sensor, measures flat surface, rod ; when measure inner hole surface, the diameter of inner hole are required>5mm, depth>22mm. |

| KS110 - Curved Surface Sensor, to measure smooth and deep cylindrical surface which radius is larger than 3mm, for the large radius smooth spherical surface and other surface also can obtain good approximation and performance, need to work with platform KA520 or KA620. |

| KS120 -very small hole Sensor, to measure the inner deep surfaces of holes with radius more than 2mm, it is better to match with platform KA520 or KA620. |

| KS130 - Groove sensor, measure flat surface, grooves with width ≥2mm, depth ≤3mm, and down step height ≤3mm, also to measuring fixture, can measure cylindrical inner surface. |

| KS131 - Deep Groove Sensor, measure groove with width wider than 3mm and depth than 10mm, or the surface roughness of step with height less than 10mm, also can used to measure the planar, cylindrical used with platform,better to work with platform KA520 or KA620. |

| KS132- 15mm Very Deep Groove Sensor, special. |

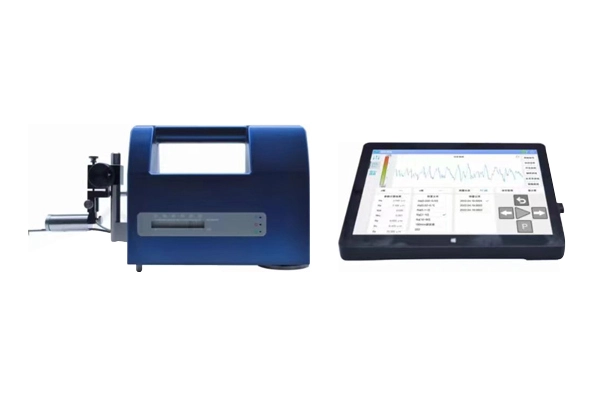

| KA520 -Metal Substrate Working platform, adjustable height 200mm. With flexible and stable operation stand and wider application range. Roughness of complex shapes can also be measured well. Measurement stand enable the adjustment of the position of stylus to be more precise and measurement to be more stable. If Ra value of measured surface is relatively low, this platform is recommended. |

| KA620 -Marble Substrate Working Platform, adjustable height 300mm. With flexible and stable operation stand and wider application range. Roughness of complex shapes can also be measured. Measurement stand enable the adjustment of the position of stylus to be more precise and measurement to be more stable. If Ra value of measured surface is relatively low, Using measurement platform is recommended. |

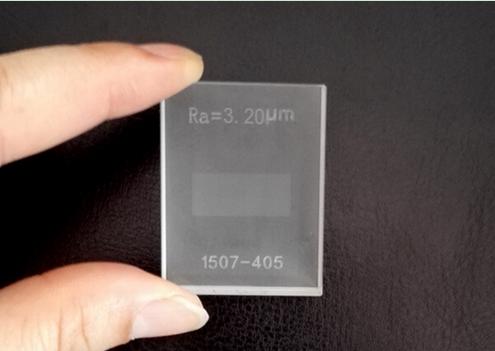

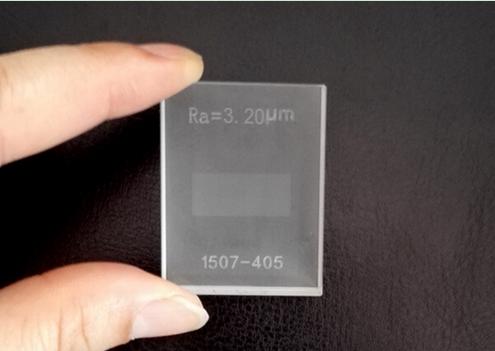

| Standard Roughness Calibration Block Multi-engraved lines (Square Wave) Made by optical glass, having high hardness, high accuracy standard roughness value, anti-scratch, has longer life than metal roughness block. Meet standard GB/T19067.1-2003 and ISO5436-1:2000 Approximation: Ra=0.1μm, 0.2μm, 0.4μm, 0.8μm, 1.6μm, 3.2μm, 6.4μm Customized Value and Sine Wave available. |

| Standard Roughness Calibration Block Single engraved lines Made by optical glass, obtaining high hardness, high accuracy standard roughness value, anti-scratch, longer life than metal roughness block. Meet standard GB/T19067.1-2003 and ISO5436-1:2000 Approximation: H10-20μm (roughness tester use filter D-P, test RT value) Customized Value available. |

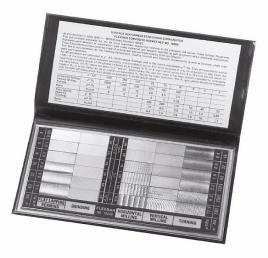

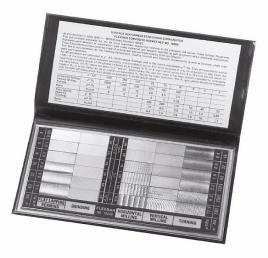

| Roughness Comparator (30 pcs/set) It contains standards of the six most important machining ways in the prevalent "AA" values. These surface roughness is for to compare and determine the degree of the surface finish by companion method and eye estimation or magnifying glass.The surface rough contrast blocks is made of 45 super carbor steel except the GCr15 which is using to plat lapping the sample block. All 30 speciments are calibrated in u''AA (Arithmetical Average) and in the metric equivalents um Ra. |

| Charge and Cable for Surface Roughness Tester Charger: US/ EU standard Cable: USB interface |

| Mini thermal printer External printer, connect by USB, suitable for Kairda models. |

| Thermal printing paper Fit for mini thermal printer and Kaidas’s tester with built-in printer Packing: 10pcs/bag · Paper Width : 57mm(56.18mm),Roll Diameter : Ø = 30 mm |

français

français Español

Español русский

русский العربية

العربية português

português