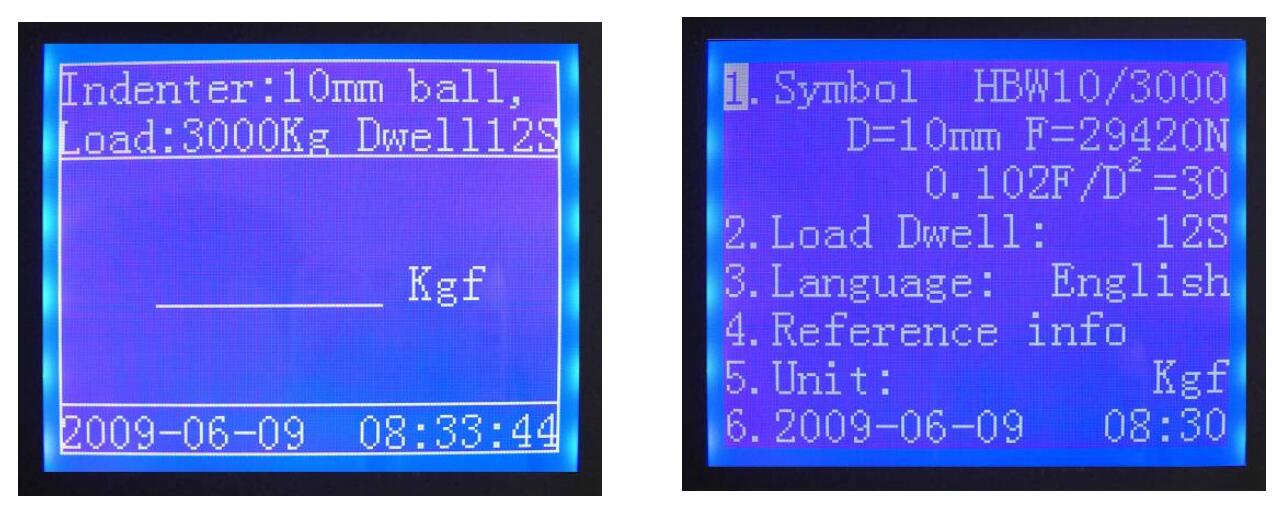

Loads: 3000kgf /29400N/, 1500Kgf /14700N/, 1000Kgf /9800N/, 750Kgf /7355N/, 500Kgf /4900N/, 250Kgf /2452N/, 187.5Kgf /1839N/, 125Kgf /1226N/, 100Kgf /980N/, 62.5Kgf /612.9N/ |

Load dwell duration time: 2s~99s, can be set and stored |

Tungsten Carbide Ball indenter: 10mm, 5mm, 2.5mm |

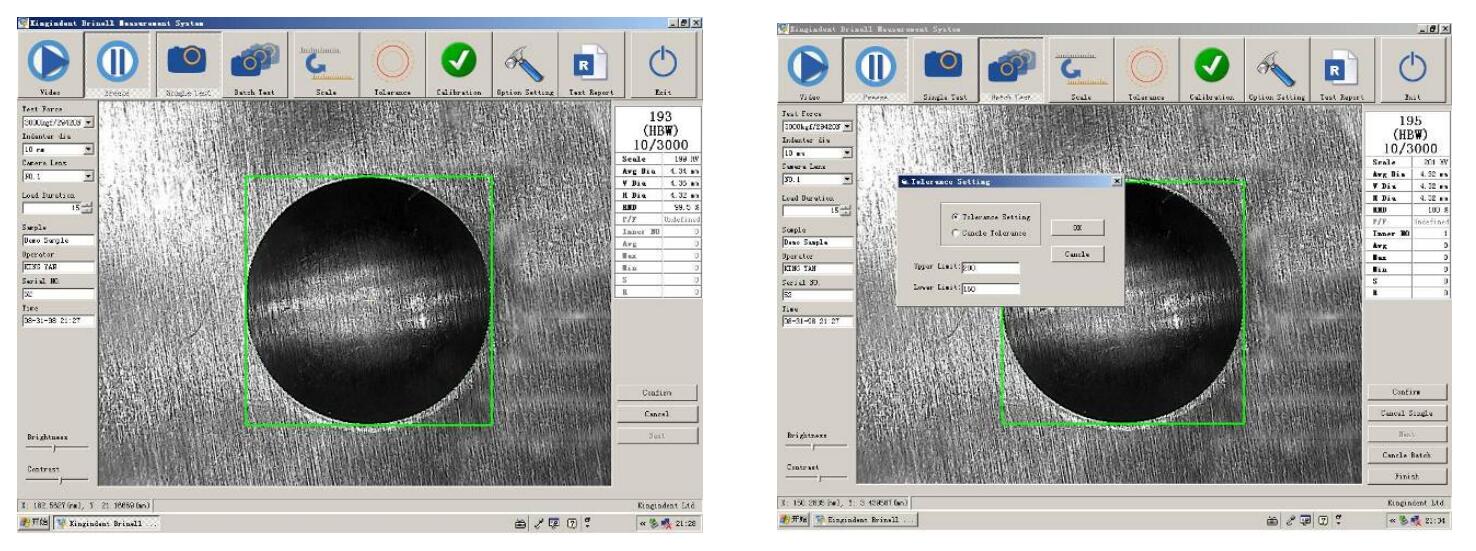

Measuring range: 3.18HBW~658HBW |

Accuracy of indention measureing: ±0.5% full scales |

Accuracy of Brinell Hardness Value: |

Hardness Range(HBW) | Error (%) | Repeatability(%) |

≤ 125 | ± 2.5 | ≤3.0 |

125<HBW≤225 | ± 2.0 | ≤2.5 |

> 225 | ±1.5 | ≤2.0 |

Max measurable height: 220 mm |

Max measurable depth: 150 mm |

Dimensions: 530mm×260mm×750mm |

Power supply: 220/110 V, 50/60 Hz, 4A |

Net Weight: 130kg |

Standard blocks: 125-350HBW10/3000, 125-350HBW10/1000 |

français

français Español

Español русский

русский العربية

العربية português

português