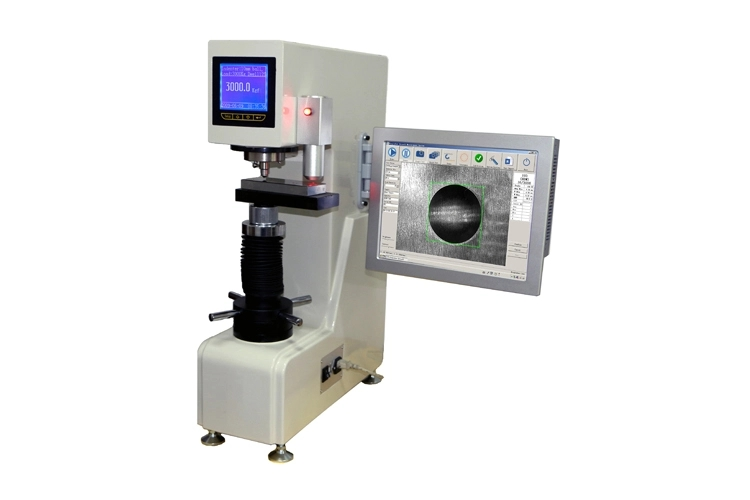

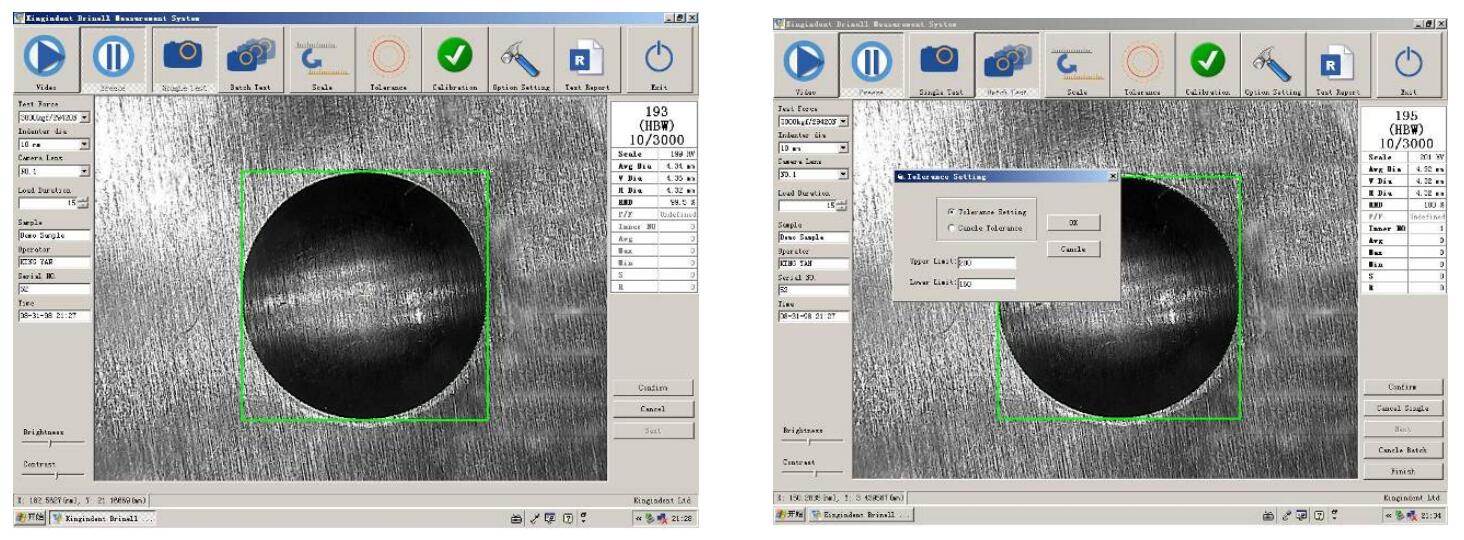

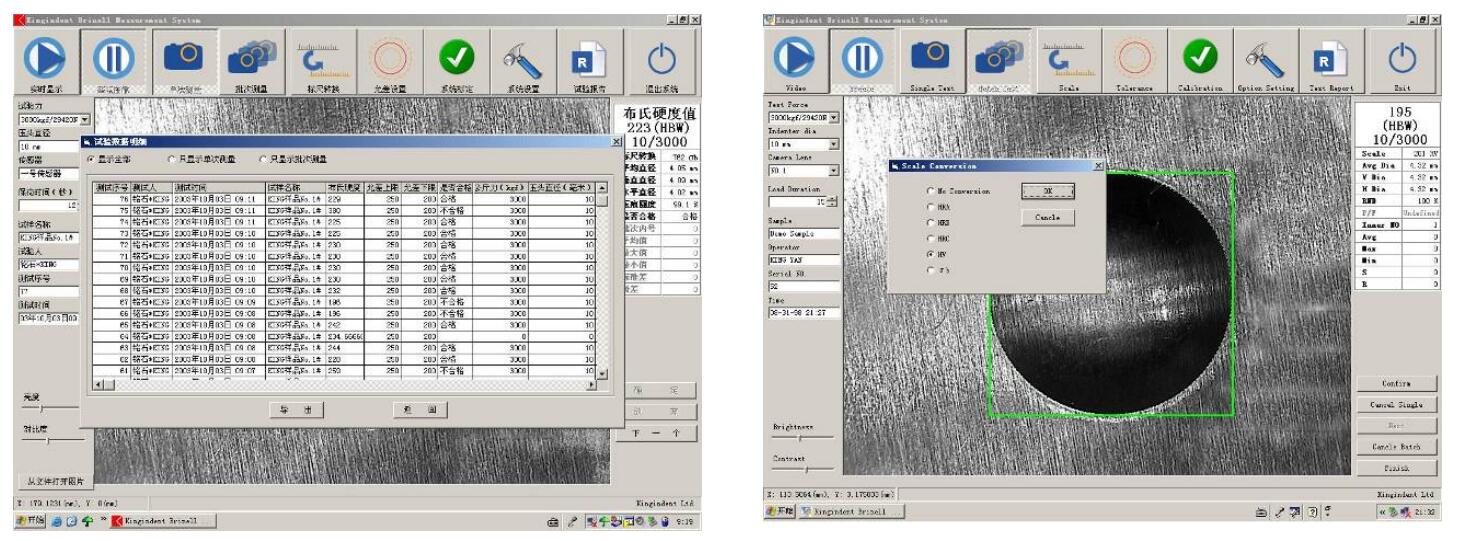

The device is equipped with a CCD camera and a PC, enabling the automatic measurement of indentations, thereby streamlining the process and enhancing accuracy. Additionally, it offers versatility in operation through three available methods: touch screen, keyboard, and mouse. This flexibility ensures that users can choose the most convenient and efficient way to interact with the system, catering to different preferences and operational requirements. This integration of technology simplifies the measurement process and improves user experience.

français

français Español

Español русский

русский العربية

العربية português

português