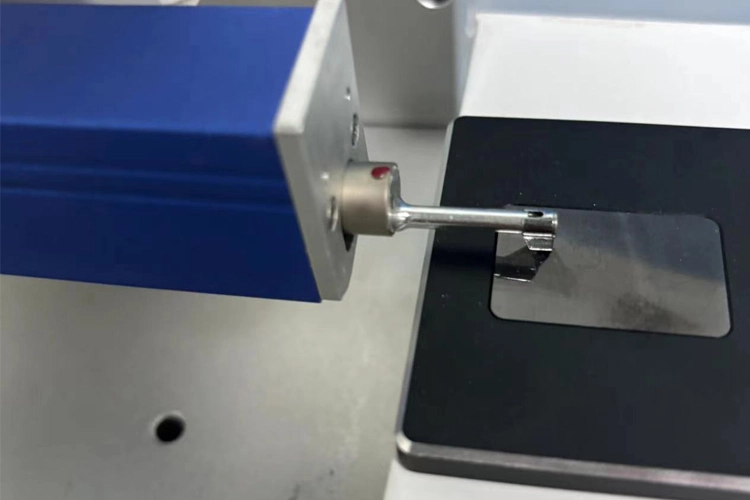

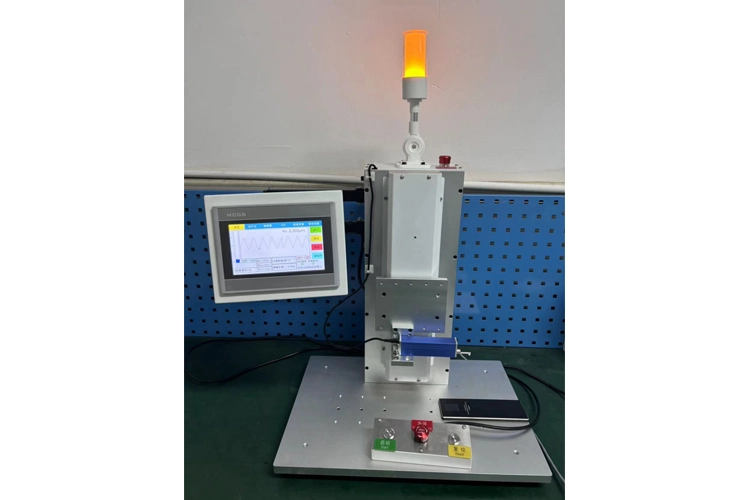

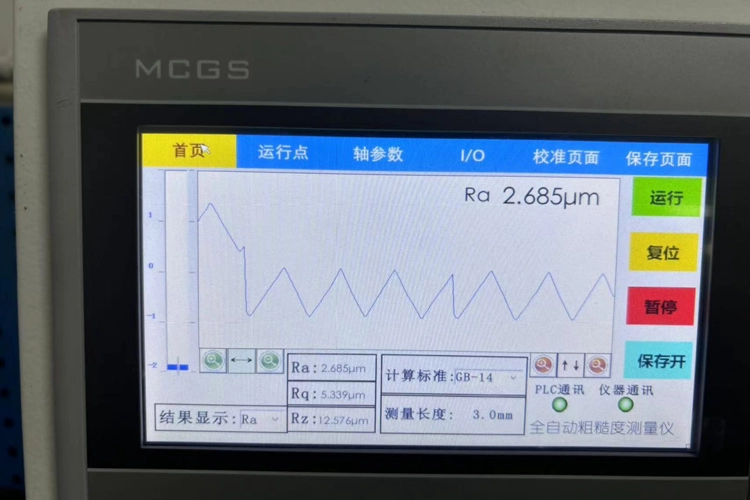

The fully automatic roughness measuring instrument is a machine that combines a roughness meter with an automated machine. This instrument is suitable for single and large quantities of products; Products with requirements for surface roughness measurement and high sampling frequency or full inspection. This machine can also be customized for different customers and measurement requirements to meet their measurement and usage needs. The purpose of developing this instrument is to achieve automatic measurement, synchronized data upload, ensure the authenticity and objectivity of measurement values, and improve measurement efficiency while reducing manual measurement intensity.

français

français Español

Español русский

русский العربية

العربية português

português