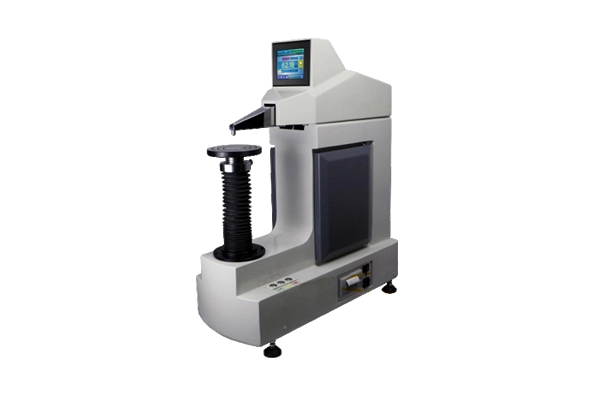

Barcol Hardness Tester, also known as Barcol Impressor, is a type of portable hardness tester mainly used for rapid hardness testing of aluminum and aluminum alloys, and fiberglass. The barcol hardness tester is simple to operate, requires no experience; it has a wide measurement range and can be used for all aluminum and aluminum alloys; it can be operated with one hand, and testing can be done by simply contacting one side of the sample.

Features of the Barcol Hardness Tester

- It is highly sensitive (with 100 scale values far exceeding those of the Webster Hardness Tester);

- It has a wide range of profile thicknesses for testing, as long as the material is greater than 0.8mm;

- The hardness test range is wide, from pure aluminum to super-hard aluminum alloys, with an effective range equivalent to a Brinell Hardness value of 25~150HBW;

- It is very convenient to use, as testing can be done by contacting the tested workpiece on one side, making it particularly suitable for measuring extra-large, extra-wide, and extra-thick materials.

Precautions for Barcol Hardness Tester

The sample should be kept clean

Before measurement, ensure that the point to be tested on the sample and its surroundings are free of dust and dirt, as fine sand particles can greatly affect the measurement results.

Selection of Measurement Points

When selecting measurement points, ensure that the distance from the edge of the sample is greater than 5mm, as being too close to the edge can affect the results; the distance between two indentations should be greater than 6mm, otherwise the interaction between the two indentations can result in inaccurate readings for the second indentation.

Effect of Oxide Film on Measurement Results

Although the oxide layer on aluminum profiles is thin, it can still affect hardness. Experience shows that an oxide film thickness of 10μm can cause the hardness measurement value to be 0.5~1HW higher. Please take this into consideration during actual use.

1. Before using the Barcol Hardness Tester, ensure that full-scale calibration and correction at calibration points are done (using the accompanying Barcol hardness sheets).

2. During measurement, the surface of the sample should be perpendicular to the indenter, and the bottom of the sample should be in contact with the anvil.

3. Apply sufficient grip force at once to generate adequate test force; slow application of force may result in lower measurement values.

4. During the measurement, maintain the stability of the sample and the instrument to avoid twisting, as this can cause measurement errors and may damage the indenter.

français

français Español

Español русский

русский العربية

العربية português

português