As an indispensable nondestructive testing tool in modern industry, ultrasonic thickness gauge is widely used in the thickness measurement of metal, plastic, ceramics, and other materials. In order to ensure the accurate measurement of the ultrasonic thickness gauge, we need to master some key skills and precautions. This article will focus on this topic and share tips for ensuring accurate measurement with ultrasonic thickness gauge.

Choose the Appropriate Ultrasonic Thickness Gauge

First of all, to ensure the accurate measurement of the ultrasonic thickness gauge, we need to choose the instrument suitable for the measurement task. The speed of sound propagation of different materials is different, therefore, the selection of ultrasonic thickness gauge should take into account the type and characteristics of the material to be measured. At the same time, we also need to choose the right instrument model according to the measurement range and accuracy requirements. When purchasing, it is important to pay attention to the performance indicators of the instrument, such as measurement range, resolution, repeatability, etc., to ensure that it meets the actual needs.

The Correct Operation of the Ultrasonic Thickness Gauge

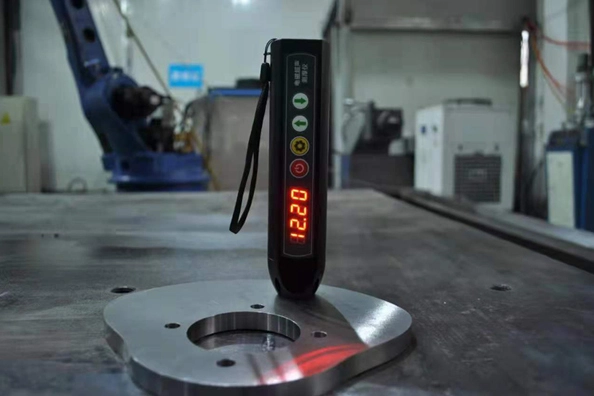

The correct operation method is the key to ensure the accurate measurement of ultrasonic thickness gauge. Before measuring, read the instrument manual carefully to understand the functions and operation methods of each component. When measuring, ensure that the probe is vertically and tightly fitted to the measured surface to avoid the impact of air gaps on the measurement results. At the same time, the probe should be kept stable to avoid shaking or tilting resulting in measurement errors. In addition, care should be taken to avoid too much or too little coupling between the probe and the tested surface, so as not to affect the propagation and reception of sound waves.

Pay Attention to Measuring the Impact of the Environment

As one of professional hardness testing machine manufacturers, we have to stress that the measuring environment also has an important influence on the accurate measurement of ultrasonic thickness gauge. First of all, the change in temperature will affect the propagation speed of sound waves, so the ambient temperature should be kept as stable as possible during the measurement process. Secondly, environmental factors such as humidity, dust, and oil pollution may also affect the transmission and reception of sound waves, so the surface to be measured should be cleaned before measurement. In addition, it is necessary to avoid measuring near interference sources such as strong magnetic fields and strong electric fields, so as not to interfere with the measurement results.

Regular Maintenance and Calibration of Ultrasonic Thickness Gauge

In order to ensure the long-term accurate measurement of the ultrasonic thickness gauge, we need to maintain and calibrate the instrument regularly. Maintenance includes cleaning probes, checking battery levels, replacing worn parts, and more. The calibration criterion is to calibrate the instrument through a standard sample or a specimen of known thickness to eliminate the error of the instrument itself. Regular maintenance and calibration can ensure the stability of the ultrasonic thickness gauge and improve the accuracy of the measurement.

In short, ensuring the accurate measurement of the ultrasonic thickness gauge, one of hardness tester types, requires us to work hard in the selection, operation, measurement environment, and maintenance calibration. By mastering these skills, we can better use the ultrasonic thickness gauge for accurate measurement, providing strong support for industrial production and quality control.

français

français Español

Español русский

русский العربية

العربية português

português